Part of what makes me a maker is that I prefer to do things myself when I can. I even cut my own hair. Nothing fancy, mind you, just a quick buzz cut with a trimmer. The tricky part, though, is cutting a good line across the back of the neck. It’s not only hard to trim, even using multiple mirrors, but it’s quite obvious when I haven’t been keeping up. Usually I ask my wife to help me, but I like to be self-reliant, and decided to see if there was a fun and educational way to trim it myself.

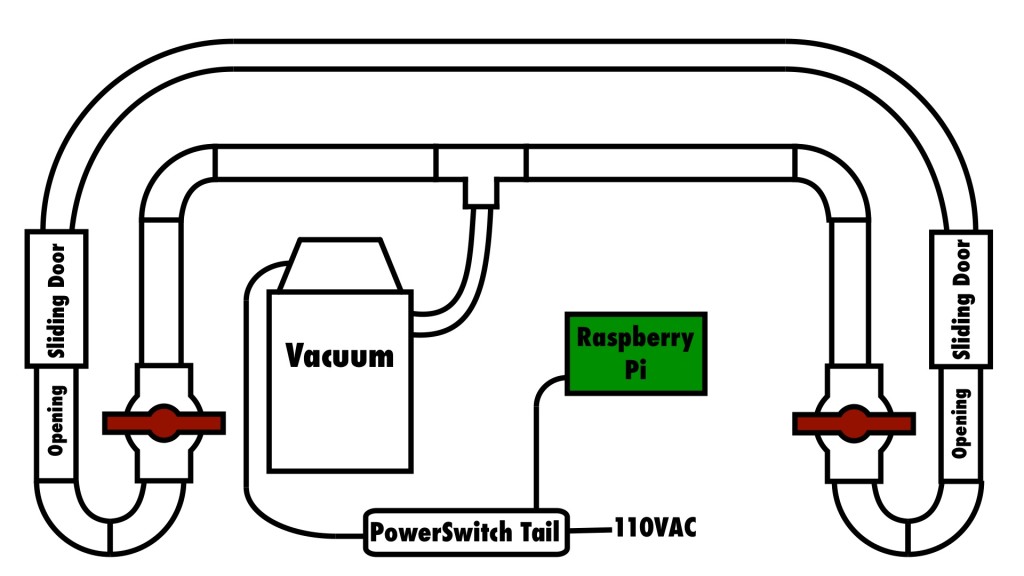

Pondering this problem, the two things that came to my mind were computer vision and automated heavy equipment. I figured I could use computer vision to track my head and the trimmer, and besides, I have long been looking for an excuse to learn about computer vision. I thought of construction equipment as a model because some control systems for bulldozers use GPS to locate the machine, and then adjust the blade according to the requirements of the site plan. In theory, the bulldozer operator could just drive back and forth over the site many times, and the control system would handle the height of the blade to result in a perfectly sculpted site. I set out to build a trimmer that I could blindly run up and down the back of my neck, and have it automatically turn on or off in accordance with its position.

Read more details on my post at Make Magazine.